My contact person

Hennlich, Industrijska d.o.o.

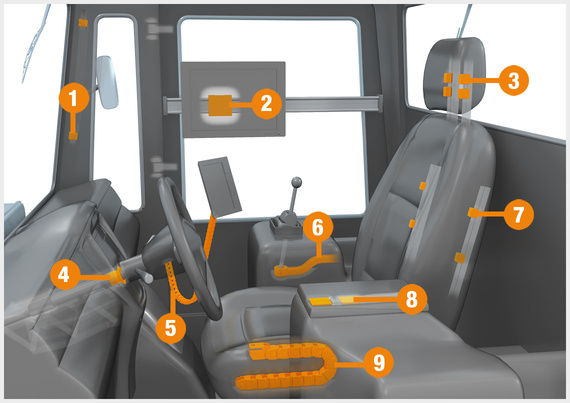

Mirror adjustment: iglidur J plain bearings

2Monitor adjustment: drylin W guide carriages

3Seat back adjustment: drylin W linear guides

4Steering column: iglidur G plain bearings

5Control elements: triflex 3D energy chain

6Hydraulic valve connection: igubal double joints

7Seat back adjustment: drylin W linear guides

8Arm rest adjustment: drylin W linear guides

9Seat adjustment: E2 energy chain and chainflex cables

Monday to Friday from 7 am - 8 pm.Saturdays from 8 am- 12 pm.

24h